Mzere wothamanga kwambiri wotentha wa Stamping Production wa ultral high-Strength Steel (Aluminium)

Zofunikira zazikulu

Mzere wopanga wapangidwa kuti upititse patsogolo njira zopangira zida zamagalimoto pogwiritsa ntchito ukadaulo wowotcha masitampu. Njirayi, yomwe imadziwika kuti kupondaponda kotentha ku Asia ndikuwumitsa ku Europe, imaphatikizapo kutenthetsa zinthu zopanda kanthu mpaka kutentha kwina, kenako ndikukankhira mu nkhungu zofananira pogwiritsa ntchito ukadaulo wa hydraulic press ndikukhalabe ndi mphamvu kuti mukwaniritse mawonekedwe omwe mukufuna ndikusintha gawo lachitsulo. Njira yopondera yotentha imatha kugawidwa m'njira zachindunji komanso zosalunjika.

Ubwino wake

Ubwino umodzi wofunikira wa zigawo zomangika zotentha ndi mawonekedwe awo abwino kwambiri, omwe amalola kupanga ma geometries ovuta kwambiri ndi mphamvu zapadera. Mphamvu zapamwamba zazitsulo zotentha zotentha zimathandiza kugwiritsa ntchito mapepala achitsulo ocheperako, kuchepetsa kulemera kwa zigawozo ndikusunga umphumphu wamapangidwe ndi kuwonongeka kwa ntchito. Ubwino wina ndi:

Kuchepetsa Kuphatikizana:Ukadaulo wopaka masitampu otentha umachepetsa kufunika kowotcherera kapena kumangirira, zomwe zimapangitsa kuti pakhale kuwongolera bwino komanso kukhulupirika kwazinthu.

Ocheperako Springback ndi Warpage:Kutentha kwa masitampu kumachepetsa zopindika zosafunikira, monga gawo laling'ono komanso tsamba lankhondo, kuwonetsetsa kulondola kwatsatanetsatane ndikuchepetsa kufunikira kowonjezeranso.

Zowonongeka Zagawo Zochepa:Zigawo zotentha zimawonetsa zolakwika zochepa, monga ming'alu ndi kugawanika, poyerekeza ndi njira zozizira zopangira, zomwe zimapangitsa kuti zinthu zikhale bwino komanso kuchepetsa zinyalala.

Kutsitsa Tonnage:Kusindikiza kotentha kumachepetsa matani osindikizira ofunikira poyerekeza ndi njira zozizira zopangira, zomwe zimapangitsa kuti pakhale ndalama zochepetsera komanso kuchuluka kwa kupanga.

Kusintha Katundu Wazinthu:Ukadaulo wopaka masitampu wotentha umalola kusinthika kwazinthu zakuthupi kutengera madera ena a gawolo, kukhathamiritsa magwiridwe antchito ndi magwiridwe antchito.

Kupititsa patsogolo kwa Microstructural:Kusindikiza kotentha kumapereka kuthekera kokweza ma microstructure azinthu, zomwe zimapangitsa kuti makina aziwoneka bwino komanso kukhazikika kwazinthu.

Njira Zosavuta Zopangira:Kusindikiza kotentha kumachotsa kapena kumachepetsa njira zopangira zapakatikati, zomwe zimapangitsa kuti pakhale njira yosavuta yopangira, zokolola zambiri, komanso nthawi zazifupi zotsogola.

Zofunsira Zamalonda

High-Speed Steel (Aluminium) High-Speed Hot Stamping Production Line imagwira ntchito kwambiri popanga ziwalo zoyera zamagalimoto. Izi zikuphatikizapo mizati, mabampa, mizati ya zitseko, ndi denga njanji ntchito magalimoto onyamula anthu. Kuphatikiza apo, kugwiritsa ntchito ma alloys apamwamba omwe amathandizidwa ndi masitampu otentha akufufuzidwa kwambiri m'mafakitale monga zakuthambo, chitetezo, ndi misika yomwe ikubwera. Ma alloys awa amapereka ubwino wa mphamvu zapamwamba ndi kuchepetsa kulemera komwe kumakhala kovuta kukwaniritsa kudzera mu njira zina zopangira.

Pomaliza, High-Strength Steel (Aluminium) High-Speed Hot Stamping Production Line imatsimikizira kupanga molondola komanso kogwira mtima kwa ziwalo zamagalimoto zooneka ngati zovuta. Ndi mawonekedwe apamwamba, kuchepetsedwa kwa ntchito zophatikizira, kuchepa kwa zolakwika, komanso kukhathamiritsa kwazinthu zakuthupi, mzere wopanga uwu umapereka zabwino zambiri. Ntchito zake zimafikira pakupanga ziwalo zoyera zamagalimoto onyamula anthu ndipo zimapereka zopindulitsa muzamlengalenga, chitetezo, ndi misika yomwe ikubwera. Invest in High-Strength Steel (Aluminium) High-Speed Hot Stamping Production Line kuti mukwaniritse magwiridwe antchito, zokolola, komanso mapangidwe opepuka pamafakitale amagalimoto ndi ogwirizana.

Kodi kupondaponda kotentha ndi chiyani?

Hot stamping, wotchedwanso atolankhani kuumitsa mu Europe ndi otentha atolankhani kupanga ku Asia, ndi njira zakuthupi kupanga kumene opanda kanthu ndi usavutike mtima ndi kutentha enaake ndiyeno zimadindidwa ndi kuzimitsidwa pansi pa kupsyinjika mu imfa lolingana kukwaniritsa mawonekedwe ankafuna ndi kulimbikitsa gawo kusintha mu zinthu zitsulo. Ukadaulo wopondereza wotentha umaphatikizapo kutenthetsa zitsulo za boron (zokhala ndi mphamvu zoyambira 500-700 MPa) kupita kudziko lokhazikika, kuwasamutsira kufa chifukwa chopondaponda mothamanga kwambiri, ndikuzimitsa gawo mkati mwa kufa pamlingo wozizirira kuposa 27 ° C / s, ndikutsatiridwa ndi nthawi yogwira mopanikizika, kuti apeze zida zapamwamba kwambiri zamphamvu za marnsitic.

Ubwino wotentha masitampu

Kupititsa patsogolo mphamvu zokhazikika komanso kuthekera kopanga ma geometri ovuta.

Kuchepetsa kulemera kwa chigawocho pogwiritsa ntchito chitsulo chocheperako kwinaku mukusunga tsatanetsatane ndi kugwa.

Kuchepetsa kufunika kolowa nawo ntchito monga kuwotcherera kapena kumangitsa.

Gawo locheperako limabwerera mmbuyo komanso kupotoza.

Zowonongeka pang'ono monga ming'alu ndi kung'ambika.

Zofunikira zotsitsa matani otsika poyerekeza ndi kuzizira.

Kutha kusintha zinthu zakuthupi potengera magawo enaake.

Zowonjezera ma microstructures kuti azigwira bwino ntchito.

Njira yosinthira yopangira zinthu yokhala ndi njira zochepa zogwirira ntchito kuti mupeze chomaliza.

Ubwinowu umathandizira kuti pakhale magwiridwe antchito, mtundu, komanso magwiridwe antchito amitundu yotentha yosindikizidwa.

Zambiri za kupondaponda kotentha

1.Hot Stamping vs Cold Stamping

Kutentha kotentha ndi njira yopangira yomwe imachitika mutatha kutentha pepala lachitsulo, pamene kupondapo kozizira kumatanthawuza kupondaponda kwachitsulo popanda kutentha.

Kupondaponda kozizira kumakhala ndi zabwino zambiri kuposa kupondaponda kotentha. Komabe, imawonetsanso zovuta zina. Chifukwa cha kupsinjika kwakukulu komwe kumabwera chifukwa cha kuzizira kopondaponda poyerekeza ndi kupondaponda kotentha, zinthu zoziziritsa kuzizira zimakhala zosavuta kusweka ndi kugawanika. Chifukwa chake, zida zoyenera zosindikizira zimafunikira pakupondaponda kozizira.

Kupopera kotentha kumaphatikizapo kutenthetsa chitsulo kutentha kwambiri musanapondereze ndikuzimitsa nthawi yomweyo mukufa. Izi zimabweretsa kusinthika kwathunthu kwa microstructure yachitsulo kukhala martensite, zomwe zimapangitsa kuti pakhale mphamvu zambiri kuyambira 1500 mpaka 2000 MPa. Chifukwa chake, zinthu zomwe zimasindikizidwa ndi zotentha zimawonetsa mphamvu zapamwamba poyerekeza ndi zoziziritsa kuzizira.

2.Hot Stamping Njira Flow

Kutentha kotentha, komwe kumadziwikanso kuti "press harding," kumaphatikizapo kutentha pepala lamphamvu kwambiri ndi mphamvu yoyamba ya 500-600 MPa kutentha pakati pa 880 ndi 950 ° C. Pepala lotenthedwa limasindikizidwa mwachangu ndikuzimitsidwa mukufa, ndikukwaniritsa kuzizira kwa 20-300 ° C / s. Kusintha kwa austenite kukhala martensite panthawi yozimitsa kumawonjezera mphamvu ya chigawocho, kulola kupanga zigawo zosindikizira ndi mphamvu mpaka 1500 MPa. Njira zopondereza zotentha zimatha kugawidwa m'magulu awiri: kupondaponda kwachindunji kotentha ndi kupondaponda kosalunjika:

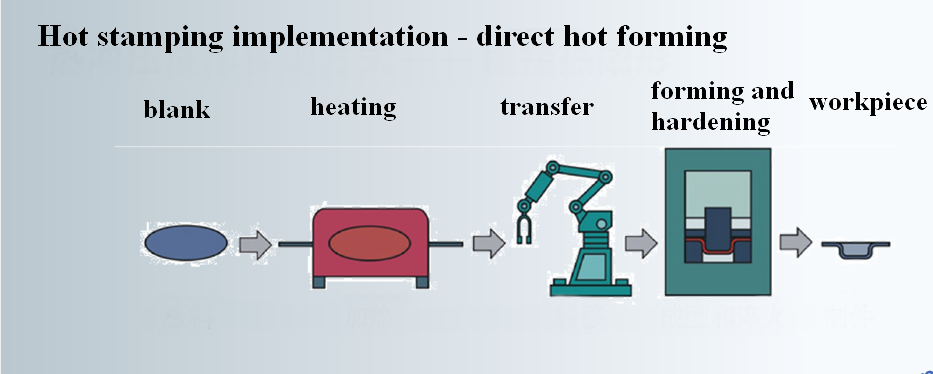

Mu kupondaponda kwachindunji kotentha, chopanda chotenthetseracho chimadyetsedwa mwachindunji mukufa kotsekedwa kwa kupondaponda ndi kuzimitsa. Njira zotsatila zimaphatikizapo kuziziritsa, kudula m'mphepete ndi kuboola mabowo (kapena kudula laser), ndi kuyeretsa pamwamba.

Fiture1: njira yotentha yopondaponda--kupondaponda molunjika

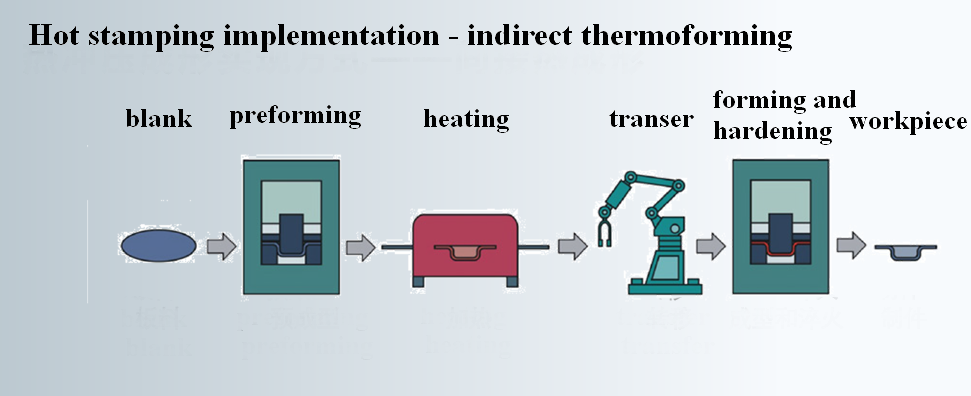

M'njira yosalunjika yotentha yopondaponda, kuzizira kopanga chisanadze kuumbika kumachitika musanalowe m'magawo otenthetsera, kupopera kotentha, kudula m'mphepete, kubowola mabowo, ndi kuyeretsa pamwamba.

Kusiyanitsa kwakukulu pakati pa kupondaponda kosalunjika ndi kupondaponda kwachindunji kotentha kumaphatikizapo kuphatikizika kwa sitepe yozizira yomwe imapanga mapangidwe asanatenthedwe mu njira yosadziwika. Popondaponda molunjika, chitsulo chachitsulo chimadyetsedwa mwachindunji mu ng'anjo yowotcha, pamene muzitsulo zotentha zosalunjika, chigawo chozizira chopangidwa kale chimatumizidwa mu ng'anjo yotentha.

Njira yoyendetsera masitampu osalunjika nthawi zambiri imakhala ndi izi:

Kupanga kozizira kopanga kale--Kutentha-kupondaponda-Kutentha--Kudula m'mphepete ndi kubowola mabowo-Kuyeretsa pamwamba

Fiture2: njira yotentha yopondaponda--kupondaponda kosalunjika

3.Zida zazikulu zopondera zotentha zimaphatikiza ng'anjo yowotchera, makina osindikizira otentha, ndi ma molds otentha

Ng'anjo Yowotcha:

Ng'anjo yotenthetsera imakhala ndi mphamvu zowotchera komanso kutentha. Imatha kutentha mbale zamphamvu kwambiri mpaka kutentha kwa recrystallization mkati mwa nthawi yeniyeni, kukwaniritsa dziko la austenitic. Iyenera kukhala yogwirizana ndi zofunikira zazikulu zopanga zopanga zokha. Monga momwe billet yotenthetsera imatha kugwiridwa ndi ma robot kapena mikono yamakina, ng'anjoyo imafuna kutsitsa ndi kutsitsa ndikuyika bwino kwambiri. Kuonjezera apo, powotcha zitsulo zosaphimbidwa, ziyenera kupereka chitetezo cha mpweya kuti zisawonongeke pamwamba pa oxidation ndi decarbonization ya billet.

Hot Forming Press:

Makina osindikizira ndiye maziko aukadaulo waukadaulo wotentha. Iyenera kukhala ndi luso lopondaponda mwachangu ndikugwira, komanso kukhala ndi makina ozizirira mwachangu. Kucholowana kwa makina osindikizira otentha kumaposa kwambiri makina osindikizira oziziritsa wamba. Pakali pano, ndi makampani oŵerengeka chabe akunja amene adziŵa bwino luso la kupanga ndi kupanga makina osindikizira oterowo, ndipo onse amadalira zinthu zochokera kunja, zomwe zimawapangitsa kukhala okwera mtengo.

Hot Stamping Molds:

Kutentha kwa ma stamping molds kumachita magawo onse akupanga ndi kuzimitsa. Popanga siteji, pamene billet imadyetsedwa mu nkhungu, nkhunguyo imamaliza mwamsanga ndondomeko yosindikizira kuti iwonetsetse kuti kukwaniritsidwa kwa gawoli kusanachitike kusintha kwa martensitic. Kenaka, imalowa mu siteji yozimitsira ndi kuziziritsa, kumene kutentha kuchokera ku workpiece mkati mwa nkhungu kumasamutsidwa mosalekeza ku nkhungu. Mapaipi ozizirira opangidwa mkati mwa nkhungu nthawi yomweyo amachotsa kutentha kudzera mu choziziritsira choyenda. Kusintha kwa martensitic-austenitic kumayamba pamene kutentha kwa workpiece kumatsika mpaka 425 ° C. Kusintha pakati pa martensite ndi austenite kumatha pamene kutentha kufika 280 ° C, ndipo workpiece imatengedwa pa 200 ° C. Ntchito yogwira nkhungu ndikuletsa kufalikira kwamafuta osagwirizana ndi kutsika panthawi yozimitsa, zomwe zingapangitse kusintha kwakukulu kwa mawonekedwe ndi miyeso ya gawolo, zomwe zimapangitsa kuti zinyalala. Kuphatikiza apo, imathandizira kusuntha kwamafuta pakati pa chogwirira ntchito ndi nkhungu, kumathandizira kuzimitsa mwachangu komanso kuziziritsa.

Mwachidule, zida zazikulu zoponyera masitampu otentha zimaphatikizanso ng'anjo yotenthetsera kuti mukwaniritse kutentha komwe mukufuna, makina osindikizira otentha kuti azitha kupondaponda mwachangu ndikugwirana ndi makina oziziritsa mwachangu, komanso ziboliboli zoziziritsa zotentha zomwe zimapanga magawo onse opangira ndi kuzimitsa kuti zitsimikizire kuti gawo loyenera kupanga komanso kuziziritsa koyenera.

Kuthamanga kozizira kozimitsa sikumangokhudza nthawi yopanga, komanso kumakhudza kutembenuka mtima pakati pa austenite ndi martensite. Mlingo wozizira umatsimikizira mtundu wamtundu wa crystalline womwe udzapangidwe ndipo umagwirizana ndi kuuma komaliza kwa workpiece. Kutentha kozizira kozizira kwa chitsulo cha boron ndi pafupifupi 30 ℃ / s, ndipo kokha pamene kuzizira kumapitirira kutentha kozizira kwambiri komwe kungapangitse mapangidwe a martensitic akulimbikitsidwa kwambiri. Pamene kuzizira kumakhala kochepa kwambiri kuposa kuzizira kozizira kwambiri, zinthu zopanda martensitic monga bainite zidzawonekera muzojambula za crystallization. Komabe, kuzizira kwapamwamba, kumakhala bwinoko, kutsika kwa kuzizira kumapangitsa kuti zigawo zomwe zapangidwazo ziphwanyike, ndipo kuzizira koyenera kumayenera kutsimikiziridwa malinga ndi momwe zinthu zilili komanso ndondomeko ya magawo.

Popeza mapangidwe a chitoliro chozizira amagwirizana mwachindunji ndi kukula kwa liwiro lozizira, chitoliro chozizira nthawi zambiri chimapangidwa kuchokera kumawonekedwe a kutentha kwakukulu kwa kutentha, kotero kuti chitoliro chozizira chomwe chinapangidwira chimakhala chovuta kwambiri, ndipo n'zovuta kupeza ndi kubowola makina pambuyo pomaliza kuponya nkhungu. Pofuna kupewa kuletsedwa ndi makina opangira makina, njira yosungiramo madzi musanayambe kuponyera nkhungu nthawi zambiri imasankhidwa.

Chifukwa ntchito kwa nthawi yaitali pa 200 ℃ kuti 880 ~ 950 ℃ pansi kwambiri kuzizira ndi kutentha alternating zinthu, ndi otentha mitundu kufa chuma ayenera zabwino structural okhwima ndi matenthedwe madutsidwe, ndipo akhoza kukana amphamvu matenthedwe mikangano kwaiye billet pa kutentha kwambiri ndi abrasive okusayidi kuvala wosanjikiza wa tinthu tadontho. Kuphatikiza apo, nkhunguyo iyeneranso kukhala ndi dzimbiri yabwino yolimbana ndi choziziritsa kukhosi kuti chitoliro chozizira chiziyenda bwino.

Kudula ndi kuboola

Chifukwa mphamvu ya zigawo pambuyo popondapo kutentha kufika pafupifupi 1500MPa, ngati atolankhani kudula ndi kukhomerera ntchito, zipangizo matani zofunika ndi zazikulu, ndi kufa kudula m'mphepete kuvala ndi lalikulu. Chifukwa chake, mayunitsi odulira laser nthawi zambiri amagwiritsidwa ntchito kudula m'mphepete ndi mabowo.

4.Common magiredi otentha mitundu zitsulo

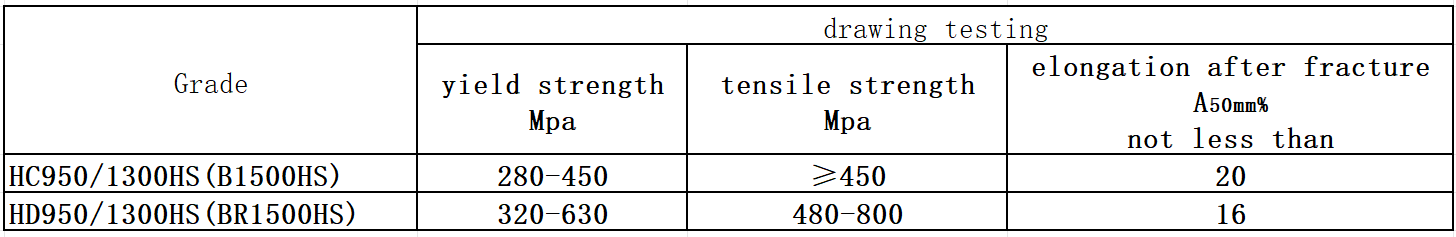

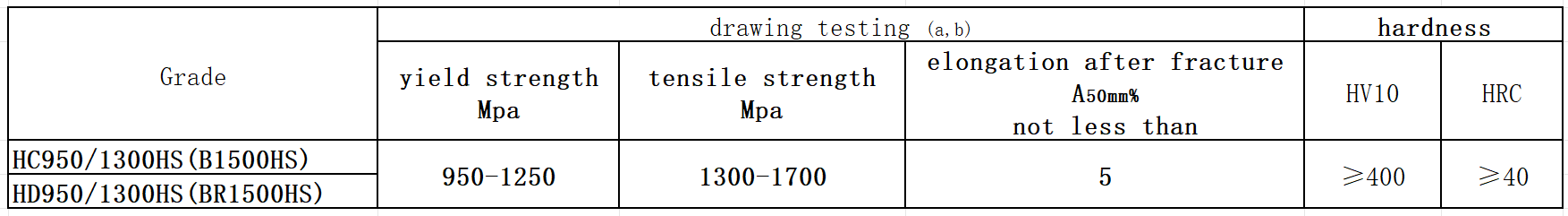

Magwiridwe asanadinde

Magwiridwe pambuyo sitampu

Pakali pano, kalasi wamba wa otentha masitampu zitsulo ndi B1500HS. Mphamvu zamakokedwe musanaponde nthawi zambiri zimakhala pakati pa 480-800MPa, ndipo mutatha kupondaponda, mphamvu yamphamvu imatha kufika 1300-1700MPa. Ndiko kunena kuti, mphamvu yamakomedwe ya 480-800MPa chitsulo mbale, kudzera pakupanga masitampu otentha, imatha kupeza mphamvu zolimba za magawo a 1300-1700MPa.

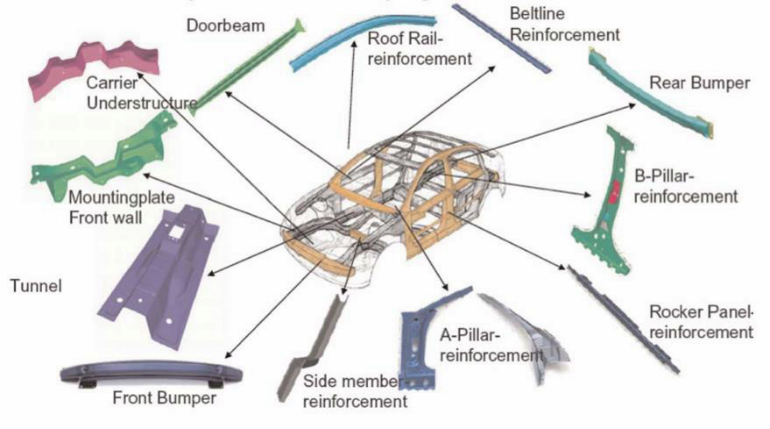

5.Kugwiritsa ntchito zitsulo zotentha zopondapo

Kugwiritsa ntchito zida zopondera zotentha kumatha kusintha kwambiri chitetezo chagalimoto ndikuzindikira kupepuka kwa thupi lagalimoto mu zoyera. Pakalipano, teknoloji yotentha yopopera imagwiritsidwa ntchito ku ziwalo zoyera za magalimoto oyendetsa galimoto, monga galimoto, mzati, B mzati, bumper, khomo la khomo ndi denga la denga ndi zina.

Chithunzi 3: Zigawo za thupi zoyera zoyenera kupondaponda kotentha

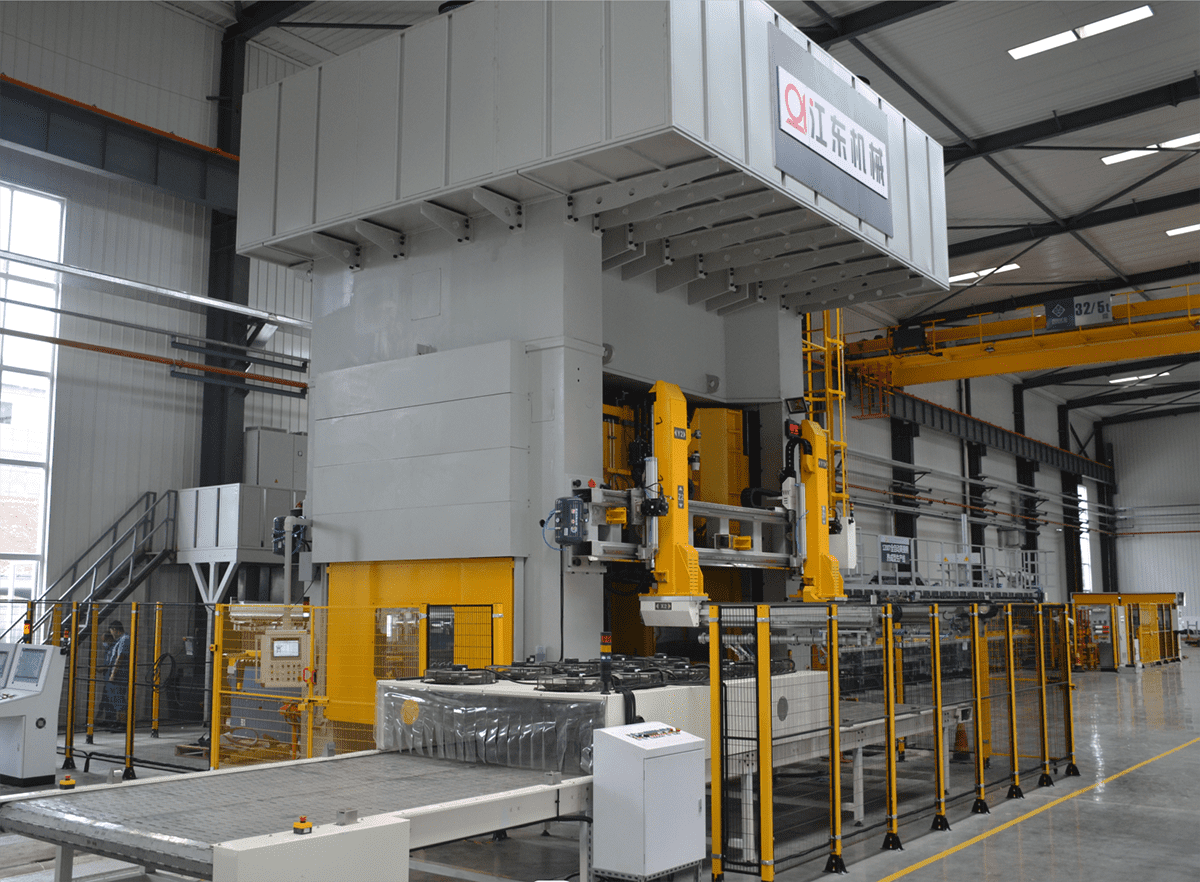

Chithunzi 4: jiangdong makina 1200 Ton Hot Stamping Press Line

Pakali pano, JIANGDONG MACHINERY otentha kupondaponda hayidiroliki atolankhani kupanga mzere njira akhala okhwima kwambiri ndi khola, mu China otentha sitamping kupanga munda ndi wa kutsogolera mlingo, ndipo monga China Machine Chida Association forging makina nthambi wachiwiri kwa wapampando wagawo komanso mayunitsi membala wa China Forging Machinery Standardization Committee, ifenso tachita kafukufuku ndi ntchito yaikulu ya dziko kufufuza ndi ntchito ya dziko liwilo zitsulo aluminiyamu, yomwe yathandiza kwambiri kulimbikitsa chitukuko cha makampani otentha masitampu ku China komanso padziko lonse lapansi.